Sustainability is a hot-button topic for various industries, including the oil and gas industry. Even some of the biggest names in the industry are shifting their portfolios to producing hydrocarbon in a low-carbon manner. In other cases, portfolios are being bolstered by clean, renewable energy resources due to the increased focus on ESG, as well as nations and corporations reaching their net-zero targets. To thrive in the present environment, a company’s ESG Strategy is now more important than ever to equally function as a future-proof mechanism.

An ESG Strategy is a business model that emphasizes social responsibility. The global organizations, shareholders, and investors you want to do business with require that you are focused on making the world a better place and also remain profitable. ESG-centric companies minimize their risk exposure by illustrating their management capacity, showing future financial performance that is sustainable, and demonstrating ethical business practices.

What is your organization’s impact on resource consumption (carbon footprint, waste water discharge, etc.)?

How does your organization represent itself and interact with the community it serves?

Are your organization’s internal practices and policies legally compliant, and do they build trust amongst consumers and society

If you are thinking about adopting an ESG Strategy for your business, it can be overwhelming trying to tackle such an important project alone. This is where IGC can help. We ensure various industries, including the oil and gas industry, have fit-for-function energy transition and integration solutions that achieve your ESG, net-zero, and low-carbon objectives. From concept to offtake agreement, our clients depend on our expertise as gas system integration and project development specialists to fill existing gaps in their processes, offer flexible, on-demand turnkey solutions, and be responsible corporate citizens focused on people, safety, and the environment.

Rather than allow CO2 emissions to arise from hydrocarbon operations, we can design and implement systems to capture these emissions and route them into geological formations via Carbon Capture Storage. Alternatively, the CO2 can be utilized for secondary purposes such as food and beverage, which can fetch a higher price point that 45Q government subsidies. Further benefits of carbon capture include:

IGC has the equipment and experience to analyze pre and post combustion gas flows to make sure the right carbon capture technology is chosen.

Membrane gas separation technology acts as a filter that allows certain molecules to permeate through while blocking others (such as CO2).

Once carbon capture has effectively taken place, and the gas is sequestered underground, our monitoring systems ensure that the gas remains stable and doesn’t escape.

This post-combustion technology cools CO2-laden flue gas and separates it to deliver a compressed CO2 stream. The process also removes other pollutants. We then take this CO2 to market via rail or trailer transport.

This process utilizes conventional solvents such as monoethanolamine (MEA) for chemical absorption to remove CO2.

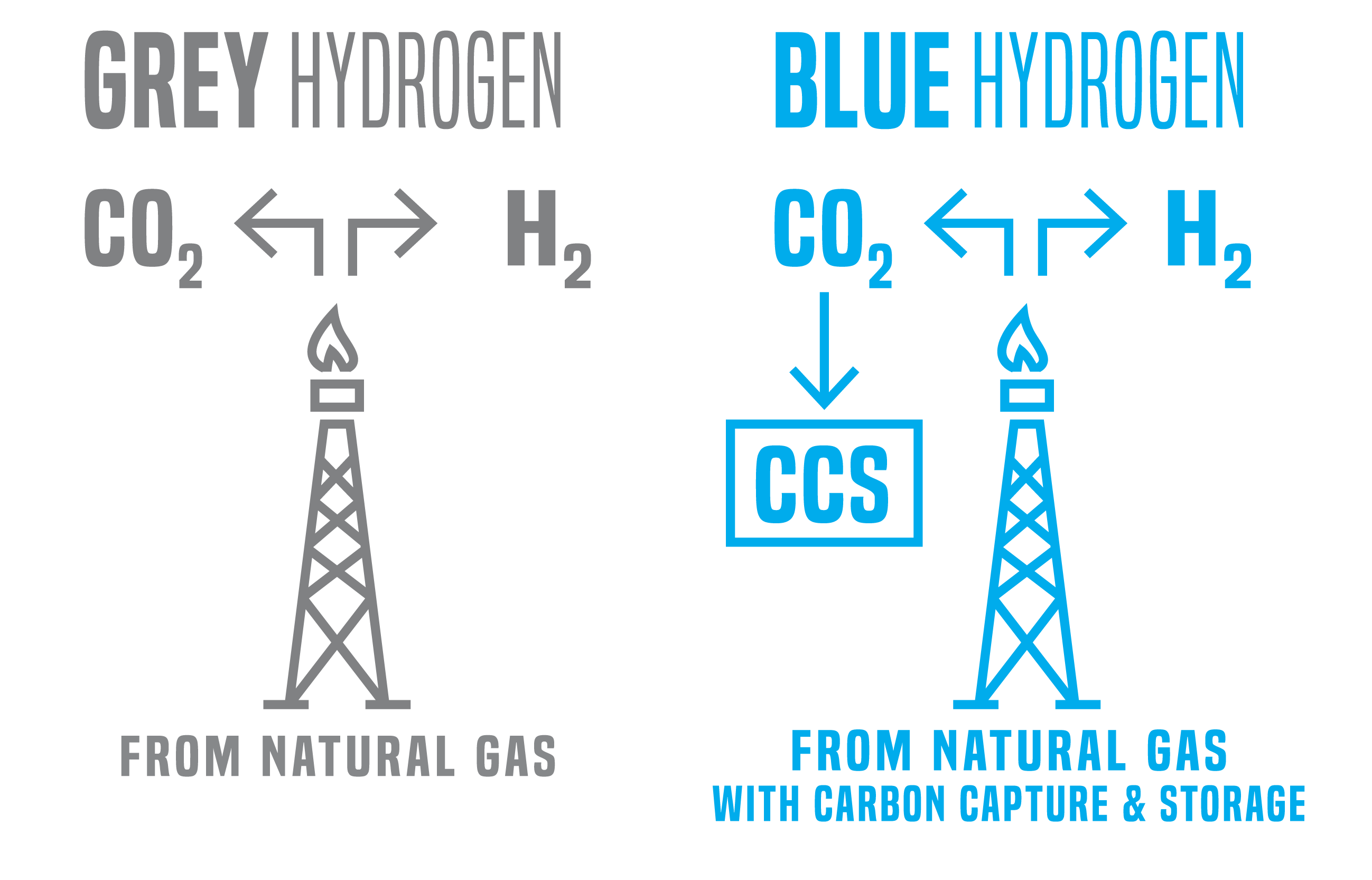

Much like carbon capture, hydrogen has taken center stage when it comes to energy transition and providing clean environmental solutions. Hydrogen can be used to electrify, but unlike fossil fuels, it is non-emitting. We assist with producing, obtaining, storing, distributing, and utilizing this critical molecule to achieve your ESG strategy needs in a climate-friendly way. Industrial Gas Consultants has strategically aligned itself with key Hydrogen economy players. Whether you are looking at grey, blue, or green projects, we can assist with everything from Pre-FEED to project commissioning. We also assist with technology selection, market analysis, and project investment.

We are not new to the hydrogen economy and have numerous resources to assist us when executing projects for our clients. We have the entire supply chain covered, so you don’t have to:

This refers to generating hydrogen on-site and then compressing it to distribute it to the end user/market. We can take the project’s scope from generation to compression. We can even step in pre-generation if required and engineer and design the complete system.

Electrolysis for carbon-free hydrogen production involves using electricity to create hydrogen by using water as feedtock. All of this takes place inside an electrolyzer. According to energy.gov, hydrogen produced via electrolysis results in zero greenhouse gas emissions, depending on the source of the electricity used. It also offers opportunities for synergy with dynamic and intermittent power generation, a characteristic of some renewable energy technologies.

Steam-methane reforming is when high-temperature steam (700 degrees celsius to 1,000 degrees celsius) is used to produce hydrogen from a methane source, such as natural gas. Steam reforming can produce hydrogen from ethanol, propane, and even gasoline.

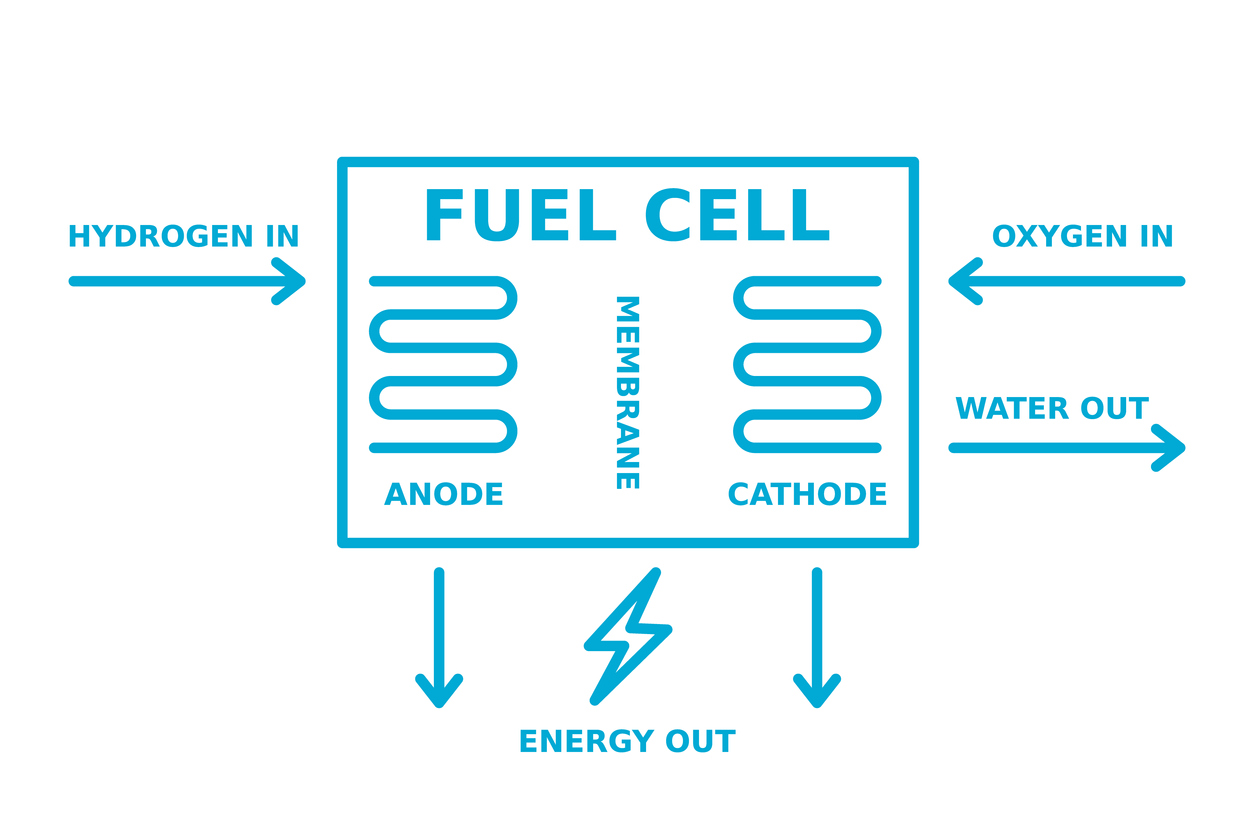

For microgrids, we use fuel cells to convert hydrogen to electricity. People who need emergency power or back-up power can use a system like this. Imagine replacing a diesel-powered generator with a hydrogen fuel cell system. But in this case, the output is electricity, and the input is hydrogen.